Realizations

The high quality level of the overhauling operation is ensured by one of the most modern machine parcs in Hungary

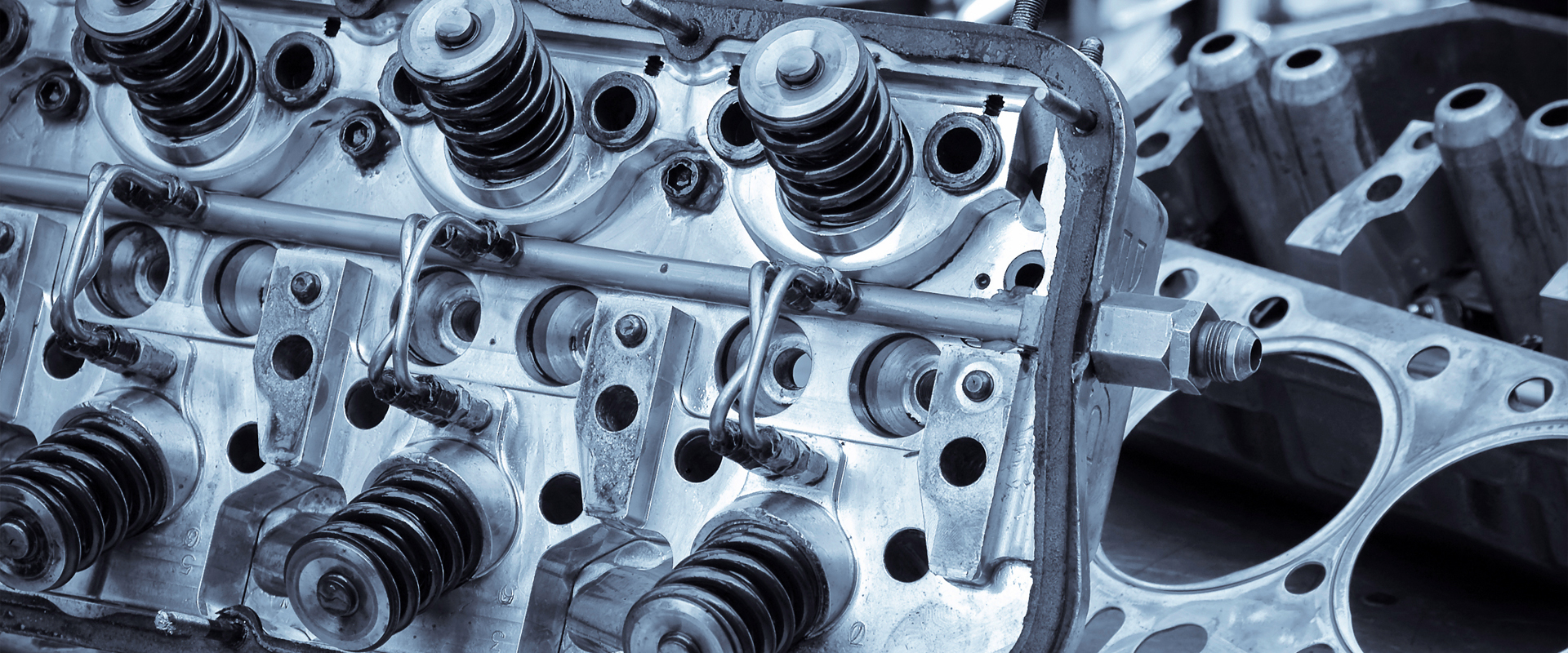

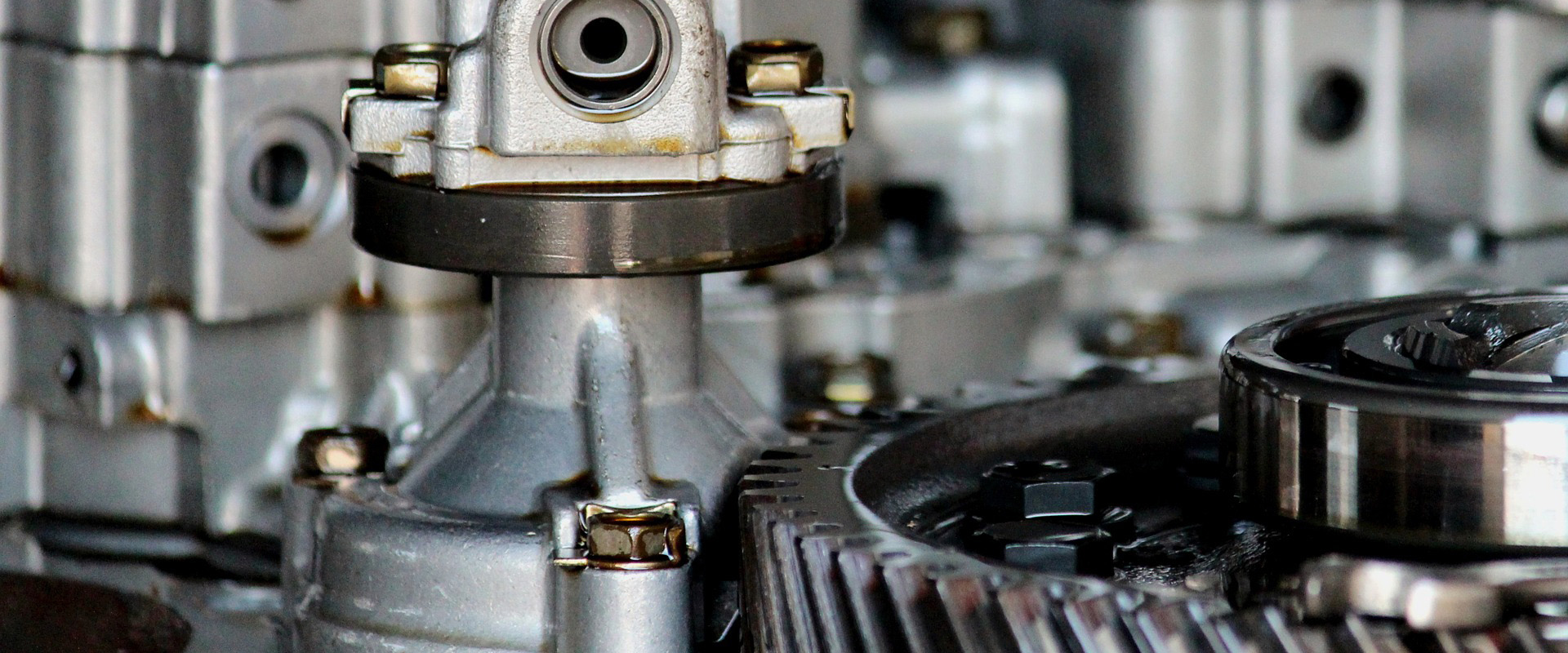

The overhauling operation consists of verifying the head conditions (crack detection), welding, pressure testing, replacing valve seats, machining valve seats, grinding valves, surfacing, and assembling.

The valve seats, valve guides and pre-combustion chambers produced by VEMU are distributed all over Hungary as well as in seven foreign countries.

BT6 Line borer: This high precision machine is used for boring the housing of the camshaft (cylinder head) and the crankshaft (engine bloc). Its machining capacity is : dia 20- 80 mm on a length of 800 mm.

CALOR 80-A Waching machine: For cleaning vehicle engine parts. The machine functions at high pressure, it is programmable, ecological and provided with oil separator.

SERDI 4.0, Valve seat and valve guide machine . A worldwide patented, high precision machine, operates with 4 air cushions and ensures an automatical centering of the machine head to the valve guide axis line. Machining capacity : seat dia 12,5- 90 mm guide dia 3- 16 mm

SERDI SPT 1500 Pressure tester: For the verification of the cooling system for leakage in the cylinder head and in the engine bloc. The tester functions with warm water and at high pressure, it is provided with an all-over-rotating fitting device, a timer and a temperature switch.